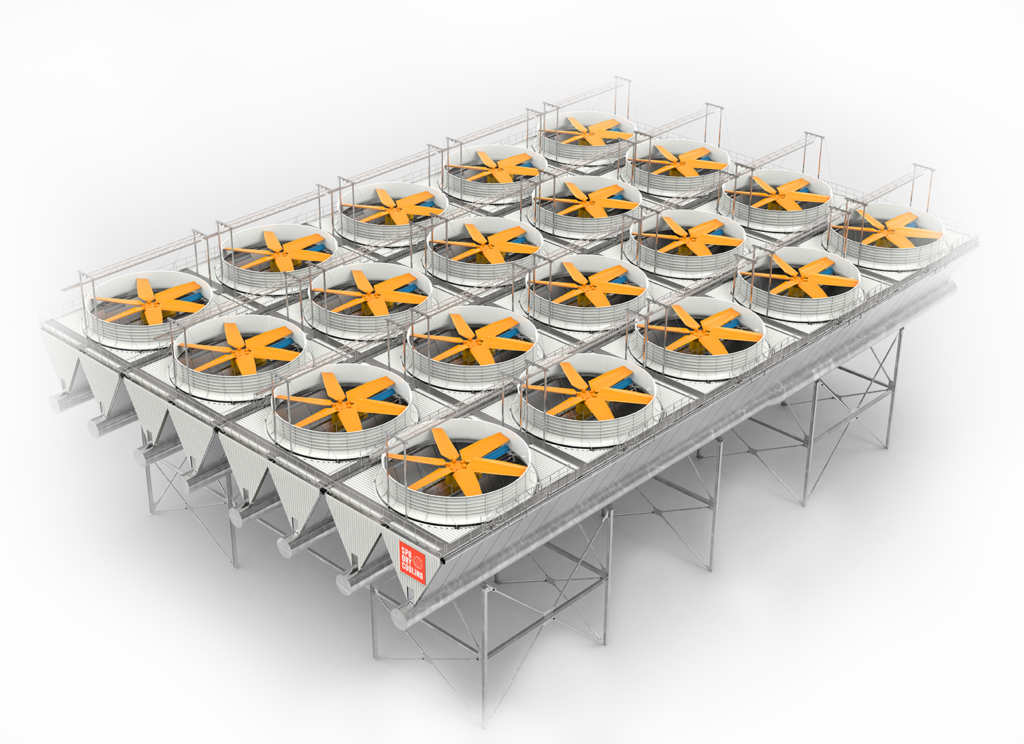

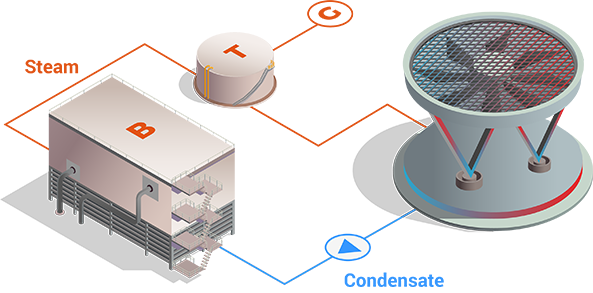

W-Style® Air Cooled Condenser

An innovative new design with induced draft capabilities for larger power plants

Products

Service & Support

Maintenance

services

Minimize the risk of downtime and expand asset`s lifespan. Tailored to your needs, SPG Dry Cooling offers a variety of maintenance services. Keeping your dry cooling system performing at optimal levels. Our programs allow you to conduct best practices, maintenance and repairs in an efficient way.