The sustainable solution for a water-smart future.

Water stress has become a worldwide problem, which means that it’s now that we need to start saving water. One mitigating solution in the power Industry Is a Wet To Dry conversion of turbine condenser cooling systems, assuring reduced water use and extended availability of power plants for peak power generation.

Water scarcity around the world intensifies in the wake of climate change. All inhabited continents of the world are impacted. Draughts plague the population and the economy, and hitting power plants hard by curtailing their generation capability.

Wet To Dry

Conversion

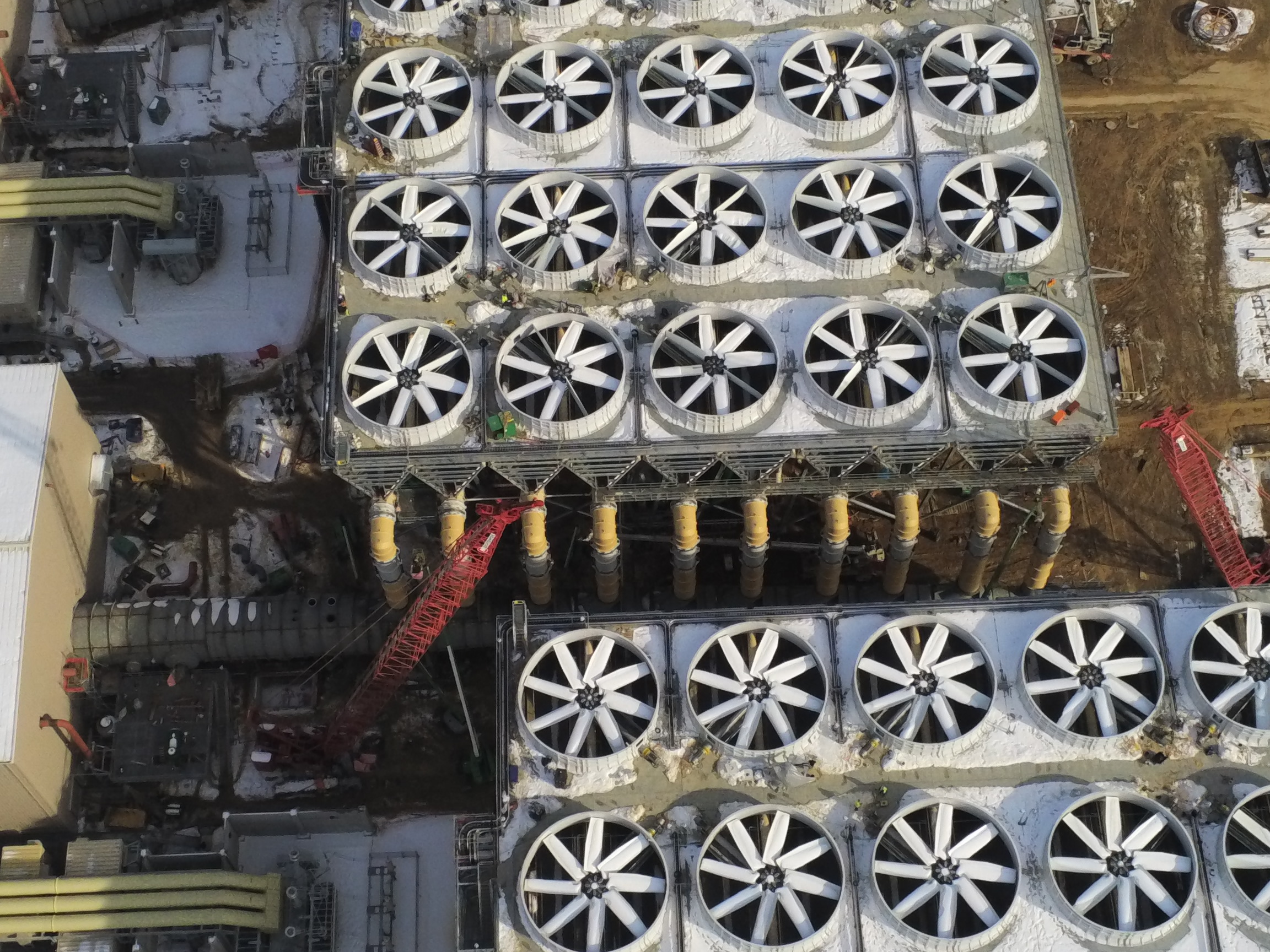

Cooling systems are the thirstiest users of water in power plants. To defy water dependence and secure sustainable power generation, the application of dry cooling systems in new build power plants is getting traction. In existing plants built with wet cooling, conversion to hybrid or to dry cooling is also a feasible solution.

01

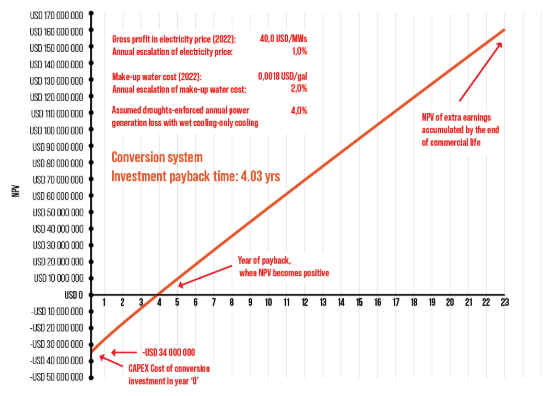

Calculating Net present value and payback time of conversion by analyzing year-round power output and water saving

02

Revenue forecasting with and without conversion

03

Definition of conversion process, technology and layout.

SPG Dry Cooling is experienced to carry out holistic, and techno-economic studies on the advantages of cooling system conversions. Analytics Include annual savings in water and enhancement of power generation availability. Our sensitivity analyses explore the impact of changing technical and economic parameters on the payback time of conversions.

Year-Round operation simulated

We accurately simulate your steam cycle year-round operation for each conversion option, using inputs including steam cycle output vs. condenser pressure variation of your steam turbine, and actual site meteorological data, in order to find the optimum power/water

balance for you.

On the image left you can see a typical printout of conversion analysis.

we can no longer ignore

the global water scarcity challenge