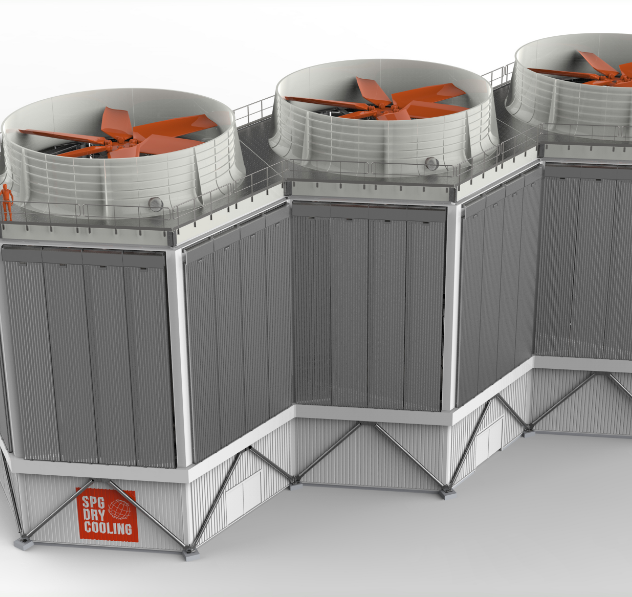

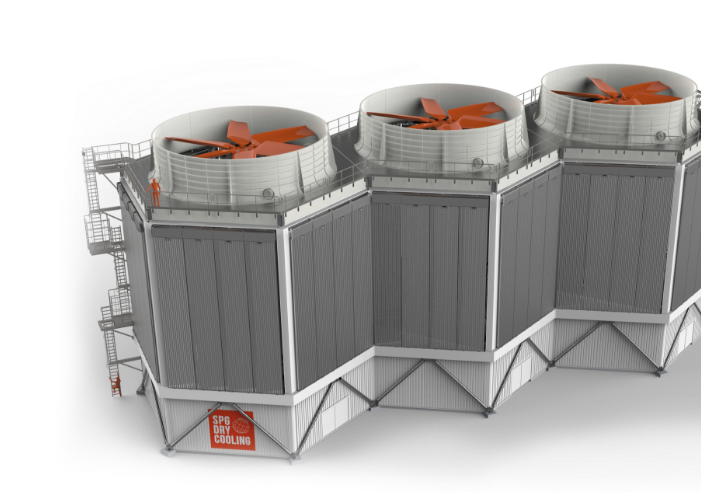

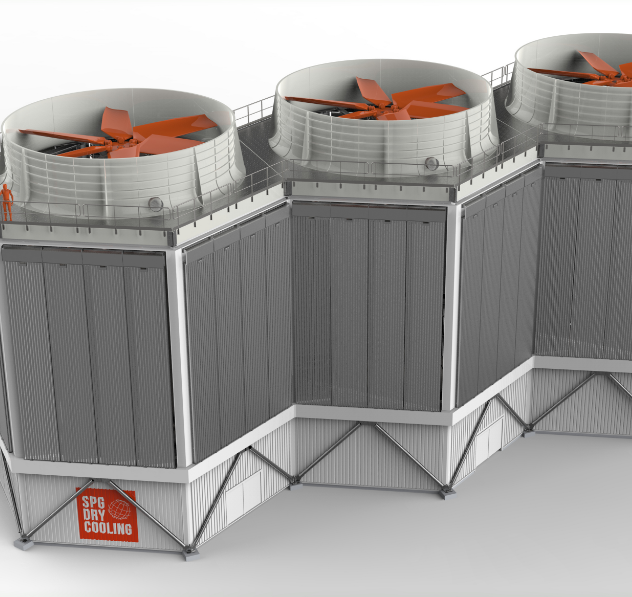

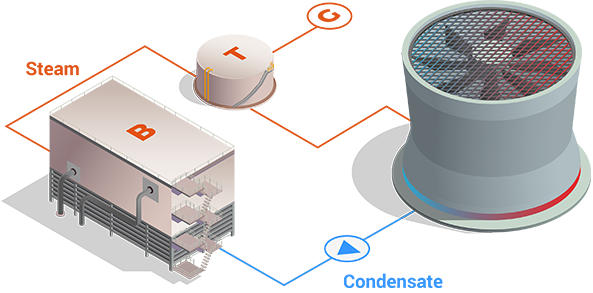

Hexacool®

Hexacool® induced draft configuration

saves up to 15% fan power consumption.

Products

Service & Support

Maintenance

services

Minimize the risk of downtime and expand asset`s lifespan. Tailored to your needs, SPG Dry Cooling offers a variety of maintenance services. Keeping your dry cooling system performing at optimal levels. Our programs allow you to conduct best practices, maintenance and repairs in an efficient way.