When calculating your total cost of ownership, you’ll learn that the greater part of the costs arises during the operating phase.

These costs are mainly energy costs, but additional expenses arise from decreased performance or changed operating conditions. In some cases, these costs can be mitigated, by increasing your net electrical output, and gaining optimal plant operation, simply by adjusting condenser operation to specific requirements.

We offer solutions such as retrofit, revamp and rebundling, refurbishming and repowering, wind mitigation system, capacity increase or a wet to dry conversion.

Whether it’s a retrofit, revamp, rebundling or repowering of your condensers, maximizing the efficiency and reliability of your power plant is essential for optimal power generation.

In today’s energy landscape, implementing an advanced modification to optimize performance is emerging as a cost-effective solution.

Our retrofitting and rebundling services are tailored to address the unique needs of your power plant, offering innovative solutions that deliver measurable improvements in performance, reliability, and efficiency.

By investing in a modification

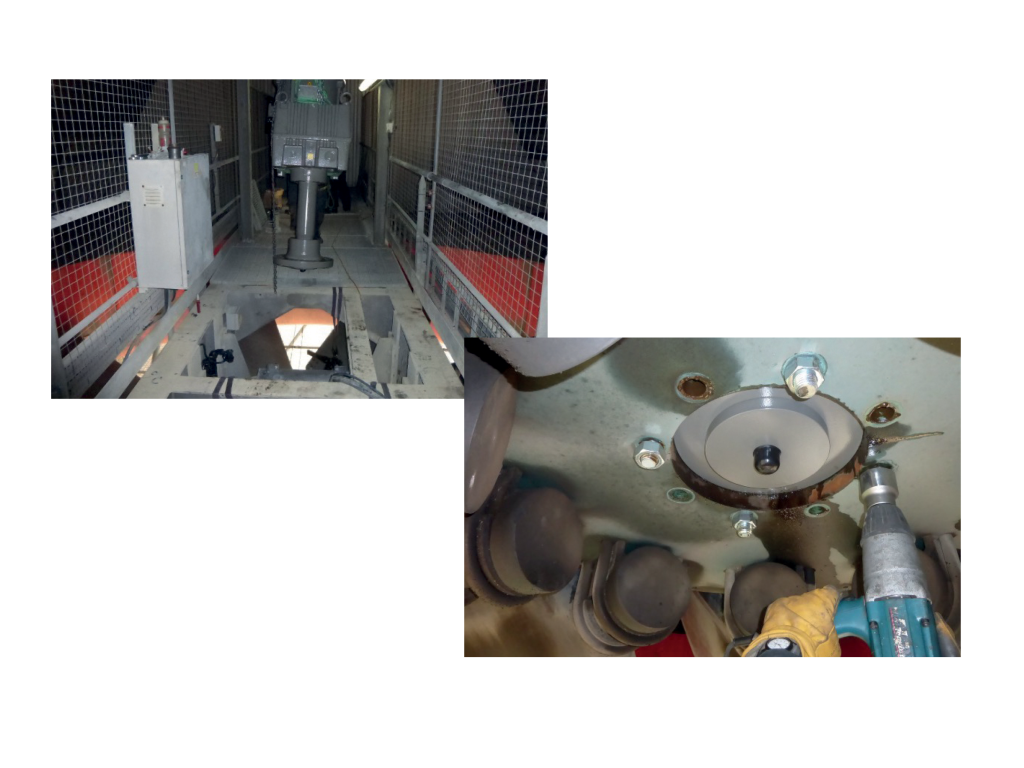

Increase the performance of your ACC with a repowering of your assets such as motors, gearbox or fan blades for better performance.

Our Patented solution to reduce the challenge of the Fan Airflow loss and Hot Air Recirculation.

Due to the crosswind at the inlet of the fan bell, the air has more difficulties entering the fans and the fan performances are disturbed by uneven flow at its entrance. The consequence is a substantial reduction of airflow on a whole street and therefore of ACC performance.

We have developed a Wind Mitigation Solution® to reduce Fan Airflow Loss and Hot Air Recirculation without degrading the ACC performance in non-windy conditions.

Enhance the capacity of your cooling asset to optimize steam turbine performance.

By increasing the efficiency of your steam cycle, you will see a direct impact on your power output, the risk of a turbine trip will be lower, and the CO2 emission will be reduced. Increasing the capacity of an existing air cooled condenser can be done with (partial) upgrading the fan groups or adding a heat exchange area.

Before initiating a capacity increase, we conduct a comprehensive analysis of your asset, taking into account:

Water saving & sustainable power generation

Water stress has become a worldwide problem, impacting various industries, including power generation. One effective solution within the power industry is the wet to dry conversion of turbine condenser cooling systems. Assuring reduced water use and extended availability of power plants for peak power generation.

Situation Upgrade of 800 MW Combined Cycle Power Plant, comprising 35 Modules arranged in a 7×5 configuration. The focus is on enhancing the ACC performance to accommodate higher steam load and ACC ageing.

Objective Increase ACC thermal capacity to accept higher steam load while respecting structural and noise constraints.

Solution SPG DC has proposed to replace all Motors & Gearboxes and adapt actual fans (blade angle setting) to increase of air flow and leading to a higher ACC thermal capacity.

We recognize the importance of efficient cooling systems and optimal performance in power generation.

In today’s sustainable market and industry 4.0, an innovative and cutting-edge approach is crucial.