Cooling systems play a critical role in power generation and industrial processes. Whether in the form of cooling towers, wet cooling systems, or dry cooling solutions, they help manage heat produced during operations, keeping equipment efficient and safe.

While many are familiar with traditional wet cooling methods that use water to remove heat, dry cooling offers a water-saving alternative. It’s especially relevant today as industries face growing pressure to reduce water consumption and environmental impact.

Dry cooling is a proven but often misunderstood technology. Despite its long history, the terminology around it can be complex and unfamiliar. To help clarify, we’ve compiled 9 key dry cooling-related terms, explained clearly by the experts at SPG Dry Cooling.

Dry Cooling

Dry cooling groups a series of technologies that cool or condense a fluid in a heat exchanger without consuming water. The heat exchangers are externally cooled by a cold air flow.

Air Cooled Condenser

An air cooled condenser is a dry cooling technology, made of a heat exchanger composed of finned tubes. Within the finned tubes, fluid is condensed, and outside air flows around the fins to remove heat. In power plants, air cooled condensers are used to condense the steam at a pressure close to vacuum.

Cooling Tower

A cooling tower is a water cooling contact exchanger in which cool air and hot water are put into direct contact. During the contact, a volume of water is evaporated, reducing the temperature of the water circulating through the tower.

Air Cooled Heat Exchanger

Air Cooled Heat Exchangers (ACHE) are part of the broader heat exchanger family and use finned tubes to cool or condense fluids. These fluids flow inside the tubes, while air moves across the fins outside to remove heat. ACHEs come in various configurations, such as induced or forced draft, and use different finned tube types based on the application. They are widely used in chemical processing, oil and gas, power generation, and other industrial sectors.

Natural Draft Condenser

A natural draft condenser is a special type of air cooled condenser where the air flow around the finned tubes is not generated by fans but by the natural draft effect. The natural draft is generated by the natural buoyancy of the warm air heated by the finned tubes and a high chimney or tower.

Waste to Energy

Waste to energy is a type of power plant that generates electricity and heat using waste as the primary fuel.

Finned Tubes

Finned tubes are the main components of a heat exchangers. They are are a series of tubes where fins have been added on the outside to increase the contact area with the outside fluid to exchange heat and between the fluid inside the tube and the fluid outside the tube.

Multiple types and shapes of finned tubes exist including round tubes, oval tubes, or flat tubes. Flat tubes, made of aluminium clad carbon steel tubes with aluminium brazed fins, so-called SRC©, are the state of the art for power plant air cooled condensers.

Indirect Dry Cooling Tower

Indirect dry condensing system coupling an indirect dry cooling tower with a steam condenser. Steam flowing from the turbine is condensed by cold cooling water in either a surface condenser or in a jet condenser. The heated water is then pumped to the indirect dry cooling tower, where heat exchangers are cool the water with ambient air. The cold air then returns to the condenser in a closed loop.

The indirect dry cooling tower (IDCT) consists of heat exchangers arranged vertically around the concrete tower. The airflow across the heat exchangers is created by the natural draft cooling tower. There is no direct contact between air and water and, therefore, there is no water consumption by evaporation as in a classical cooling tower.

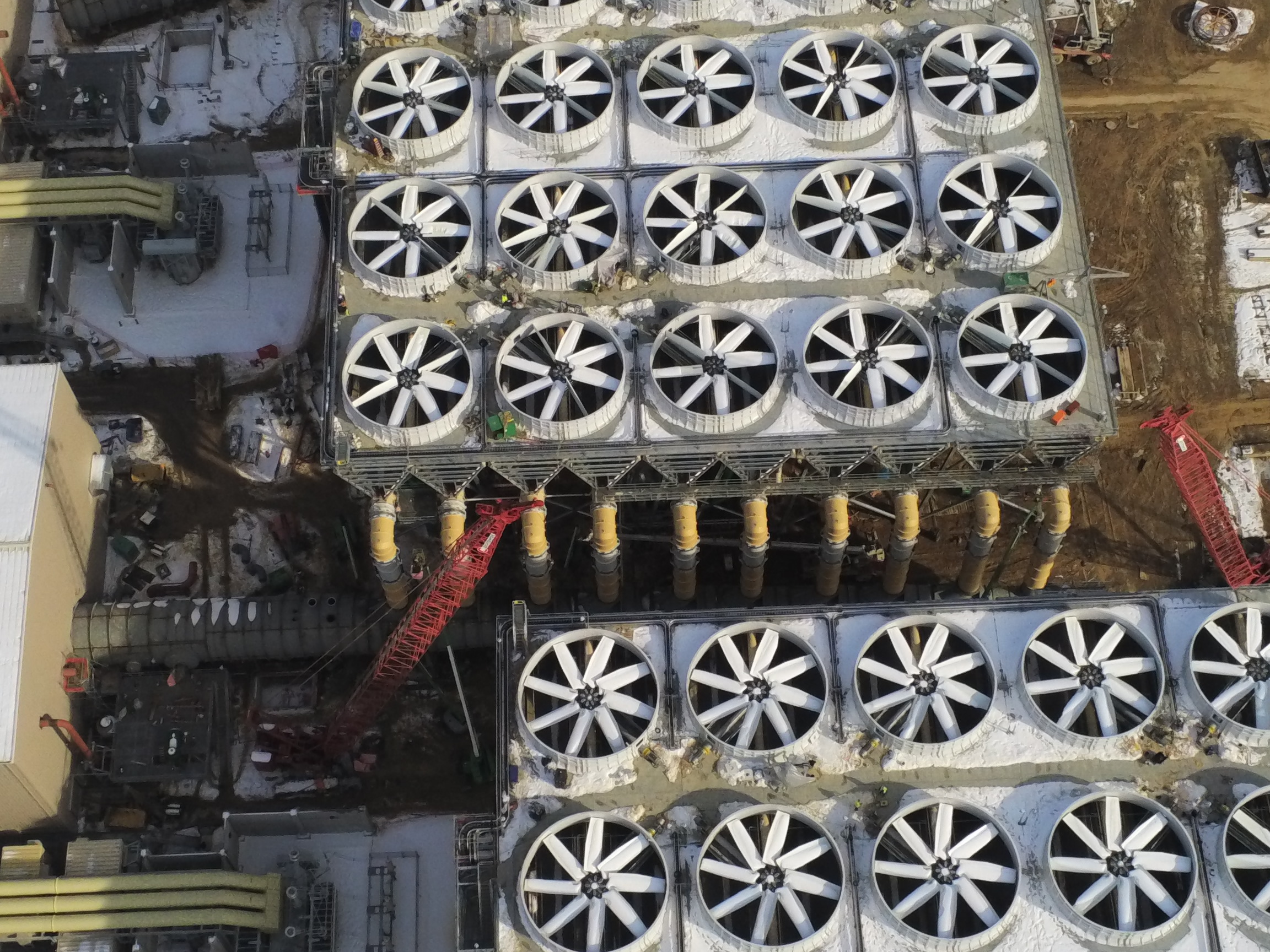

Mechanical Indirect Dry Cooling Tower

The mechanical draft indirect dry cooling tower is an IDCT, where airflow across the heat exchanger is created by large fans instead of a high natural draft tower. This solution limits the total height of the installation and gives more flexibility for site selection.

Why choose SPG Dry Cooling for

your dry cooling solutions?

SPG Dry Cooling is a global leader in air cooled condensers & coolers with equipment installed all around the globe. We offer several dry cooling solutions which fall under many international patents. SPG Dry Cooling has a workforce of 700+ professionals across the globe, being able to operate in all climates in conditions.