As environmental regulations tighten and public pressure grows to reduce water usage, power generators are shifting away from once-through river or ocean wet cooling systems. Instead, many are turning to dry cooling condenser solutions. This shift is driving increased interest in retrofitting existing plants and designing new ones with dry cooling systems.

Why Dry Cooling is the best choice?

When dry cooling is considered early in a new plant’s development, it opens up significant advantages. Most importantly, plant locations are no longer restricted to areas near large water sources. This flexibility broadens siting options. It also speeds up permitting, as dry cooling avoids the thermal pollution concerns that often delay water-cooled projects.

In addition to environmental benefits, dry cooling offers major cost savings. Air is a free cooling medium, unlike water, which comes with acquisition, treatment, and disposal costs. Dry cooling also eliminates the need for biocides and water treatment chemicals. Plus, cleaning and maintenance costs are about 75% lower than those of wet cooling systems.

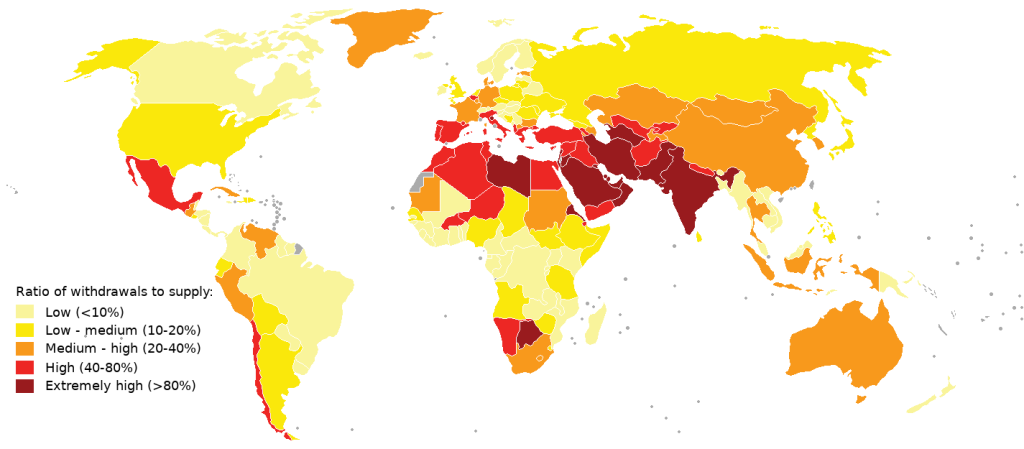

How SPG Dry Cooling Is Addressing Water Scarcity in Power Generation

Water scarcity is a growing global concern, and the power industry is under increasing pressure to reduce water usage. At SPG Dry Cooling, we actively support this transition by delivering dry cooling solutions that eliminate the need for water in the cooling cycle.

Dry cooling systems are already making a difference across various power generation sectors. They are widely used in:

- Combined cycle power plants

- Biomass, waste-to-energy, and cogeneration facilities

- Coal and LNG installations

- Concentrated solar power projects

By removing the dependency on water, these systems not only protect natural resources but also provide greater flexibility in plant location and reduce permitting timelines.

To tackle current market challenges, SPG Dry Cooling has developed two innovative technologies:

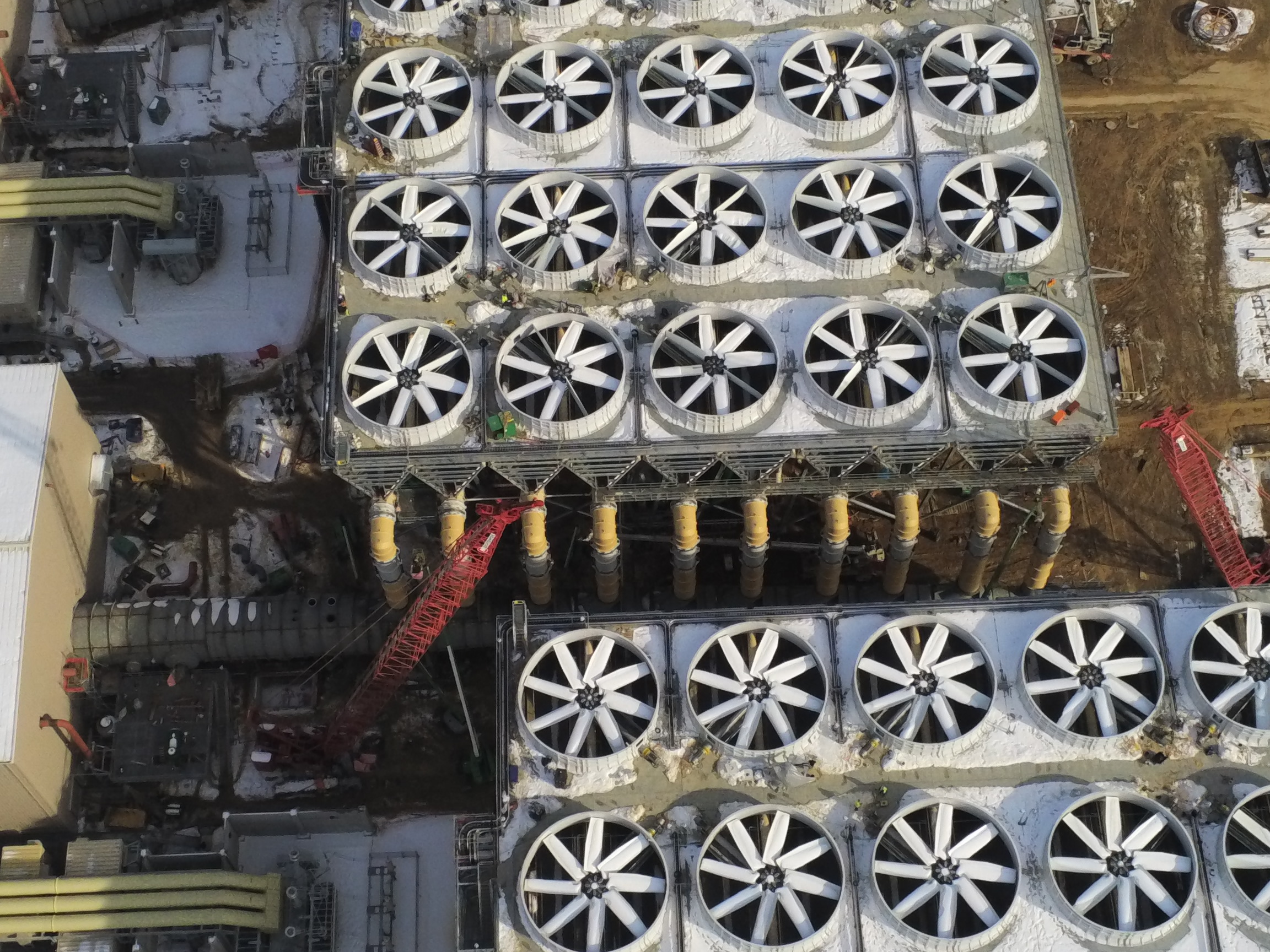

- ModuleAir® features an alternative A-frame design with shop-assembled parts that serve as structural components, ducts, and heat exchanger bundles. This modular approach improves construction efficiency and adaptability.

- W-style ACC™ offers a compact layout that minimizes footprint, height, weight, and wind sensitivity—making it ideal for space-constrained or windy sites.

These solutions demonstrate how we continue to lead in innovation and adaptability while supporting our clients in navigating environmental and regulatory demands.

Who benefits from dry cooling innovation:

- Project developers from utilities and independent power producers

- Owners and operators of utility and industrial boilers and GTCC plants

- Plant managers, engineers, and maintenance teams

- Corporate engineering teams

- A&E firms, including project managers and planners

With over 172,000 MW of installed capacity worldwide, SPG Dry Cooling remains the global leader in dry cooling system design, manufacturing, and service. Our extensive product range supports coal, gas, solar, biomass, and geothermal power generation—delivering sustainable performance without water dependency.