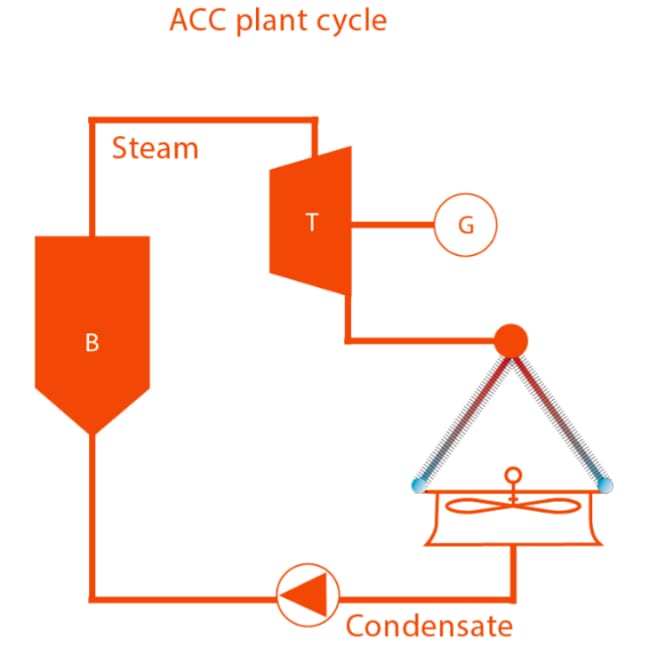

An air cooled condenser (ACC) is a type of direct dry cooling system that condenses steam inside air-cooled finned tubes. As ambient air flows across the fins, it removes heat from the steam inside, enabling the condensation process. In thermal power plants, steam from the turbine exhaust enters the ACC, where it condenses. Afterward, the condensate flows back to the boiler, completing the closed loop.

Because the turbine exhaust steam is at low pressure, the ACC operates near vacuum conditions. To maintain performance, an air evacuation unit continuously removes non-condensable gases from the system.

Air cooled condensers work well for power plants in water-scarce area

Air cooled condensers (ACCs) are widely used in thermal power plants, including combined cycle, concentrated solar, coal, biomass, and waste-to-energy facilities. Because these systems do not rely on large volumes of cooling water, they allow much greater flexibility in choosing plant locations. Operators can build plants in areas where water is limited, regulated, or expensive. At the same time, ACCs help maintain efficient performance without relying on traditional wet cooling methods.

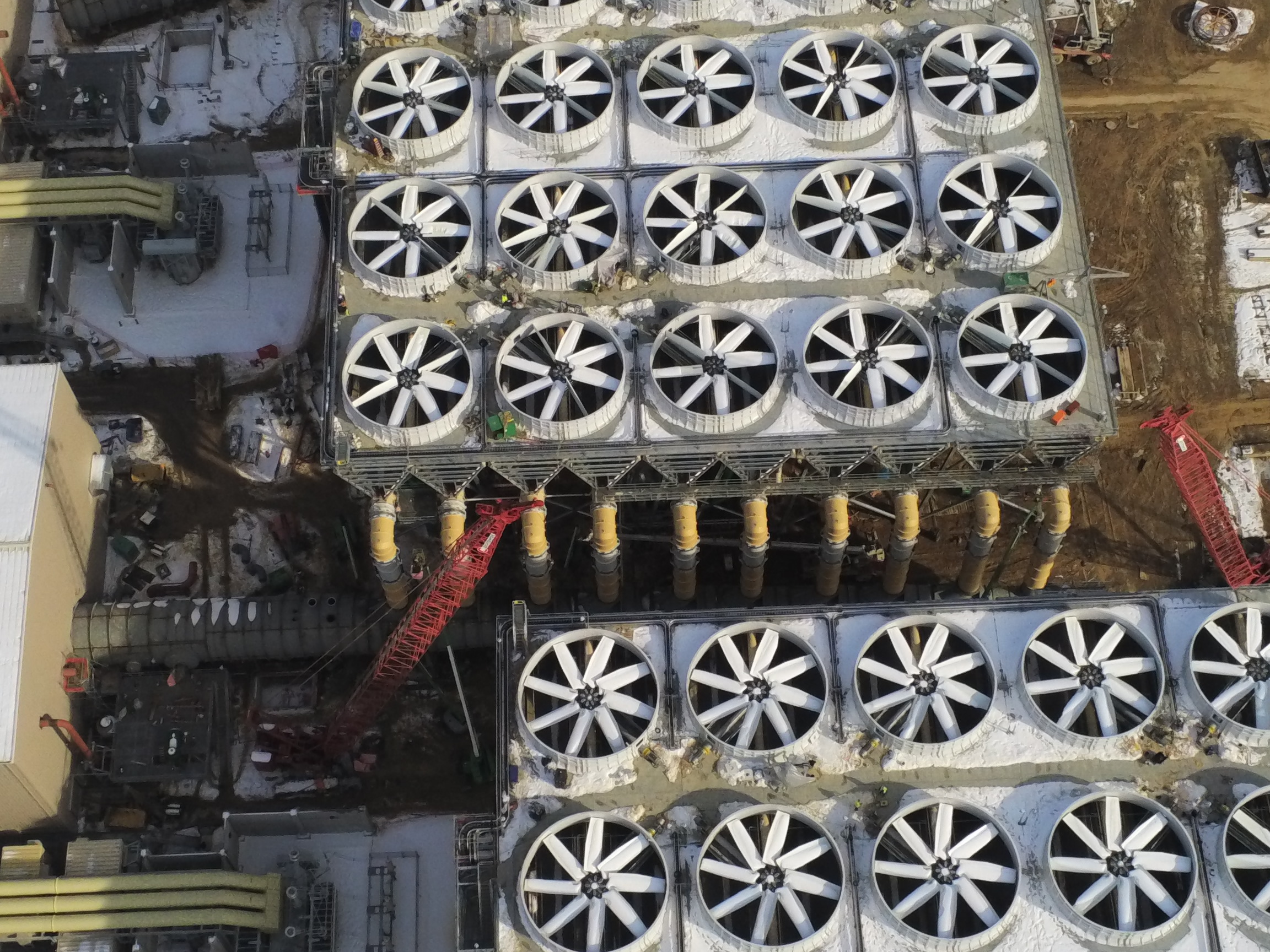

The building blocks of an air cooled condenser

n air cooled condenser consists of multiple modules arranged in parallel rows. Each module holds several finned tube bundles. Large axial fans drive ambient air across the finned tubes, enabling effective heat exchange and steam condensation.

Air cooled condensers (ACCs) come in a variety of designs beyond the traditional A-frame. At SPG Dry Cooling, we offer a range of advanced solutions, including the BoxAir ACC®, Hexacool®, ModuleAir®, and W-Style ACC®, each tailored to meet specific performance, footprint, and environmental needs.

A typical ACC installation includes several key components:

- A supporting steel structure

- Steam ducting connected to the steam turbine

- Heat exchangers with finned tubes

- Axial fans, motors, and gearboxes

- Auxiliary systems such as condensate and drain pumps

- Condensate and duct drain tanks

- Air evacuation units

- All necessary piping and instrumentation

Together, these elements form an integrated cooling system that efficiently condenses steam and returns the condensate to the boiler in a closed loop without relying on water.

Why choose SPG Dry Cooling for

your dry cooling solutions?

SPG Dry Cooling is a global leader in air cooled condensers and coolers, with equipment installed worldwide. We provide a range of dry cooling solutions protected by multiple international patents. With over 700 professionals on our team, SPG Dry Cooling operates successfully in all climates and challenging conditions around the globe.