Today we spoke with Michel Vouche, one of our founding engineers and Vice President of Engineering and Technology. With over 30 years at SPG Dry Cooling, Michel has played a key role in shaping our innovations. He shares his thoughts on the company, our progress, and his vision for the future.

1. What is your role and for how long have you been at this company?

I am the VP of Engineering and Technology. In this role, I am responsible for all the engineering functions from design to correct execution and on to quality control and the scheduling of engineering activities to meet project demands. In addition, I am also responsible for all engineering innovations and product advancements. I have been with the company for over 30 years now and am still enjoying all of it!

2. What is your vision for SPG Dry Cooling?

I’m the Vice President of Engineering and Technology. I lead all engineering functions—from design and execution to quality control and scheduling. My role also covers innovation and product development. I’ve been with the company for over 30 years, and I still enjoy every part of it!

3. We just launched two new products. Could you give us more information about them?

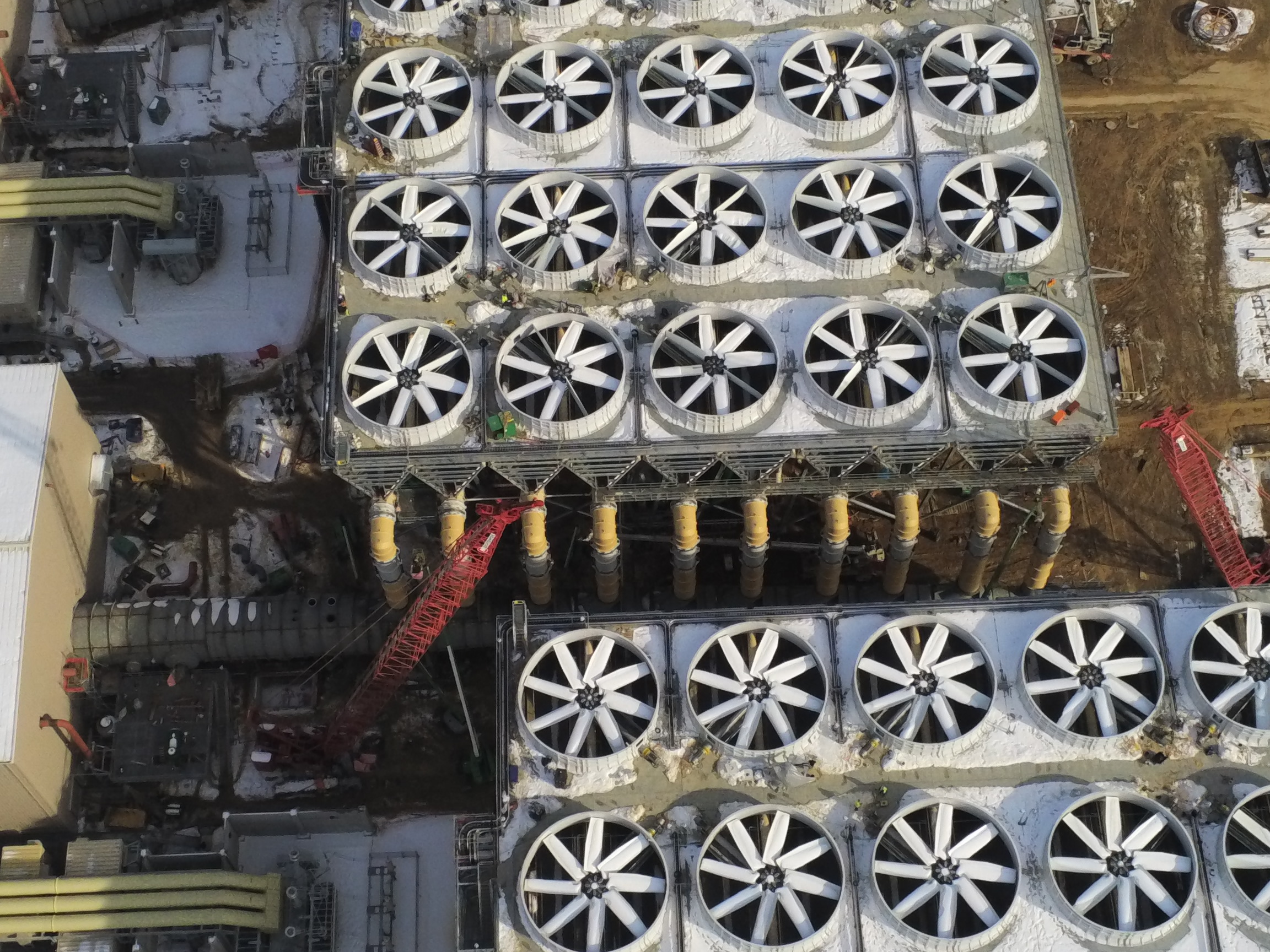

The W-Style ACC® is an induced draft air-cooled condenser for medium to large power plants (20–1000 MW). Its unique design significantly reduces the amount of structural steel, cutting costs. It also minimizes wind sensitivity, improving ACC performance and overall plant efficiency. The modular design speeds up installation, lowers costs, and increases safety on site.

We also introduced the BoxAir ACC®, designed for applications from 1 to 30 MW. This fully standardized ACC allows for fast delivery. It reduces investment costs and simplifies installation—improving both quality and safety.

4. How has the dry cooling industry been transformed over the past few decades?

Ten years ago, there were only a few dry cooling suppliers. Since then, new competitors have emerged from various continents, often offering similar products with little technical difference. In contrast, we focus on innovation—expanding our product range to meet evolving client and industry needs.

Today, on the other hand, we’re encountering different types of power plants that take into account sustainability as a key ideal. Of course, the requirements of a solar plant are totally different from coal power plants but players in both industries seem to have adjusted their outlook. What’s more, in comparison to wet cooling, we are now seeing more and more that dry cooling is being used globally, not only in dry countries but also in countries where acquiring a permit for water-use is difficult.

5. What makes SPG Dry Cooling stand out from its competitors?

At SPG DC, we have vast experience in dry cooling and are one of the very few companies in existence for over 10 years now. For me, it’s clear that the knowledge and experience of our team is immense and extensive. We are able to design and deliver specialised solutions in any country in the world. And importantly, we can ensure the quality of our finned tubes, which is the key element of dry cooling equipment. This, of course, is due to the fact that the factory in which our tubes are produced is fully owned and managed by us. We are one of the very few dry cooling companies that can offer a variety of products, adapt to different client requirements, and be a sound engineering partner to resolve any existing operational issues. Reliable and sound engineering is the key contributor to our success.

Why choose SPG Dry Cooling for

your dry cooling solutions?

SPG Dry Cooling is a global leader in air cooled condensers & coolers with equipment installed all around

the globe. We offer several dry cooling solutions which fall under many international patents. SPG Dry Cooling has a workforce of 700+ professionals across the globe, being able to operate in all climates in conditions.